Did you know that about 80% of construction projects use RFQs?

Construction’s ever-changing world demands a clear understanding of RFQ meaning to achieve project success. A request for quote (RFQ) helps organizations compare offers and select vendors that provide the best value, making it a standard business practice for getting specific products or services.

RFQs make the procurement process smoother with clear communication and quick vendor selection that ends up saving time and money. The process works faster than a Request for Proposal (RFP), especially when you have high-volume or low-value items.

You should become skilled at creating effective RFQs if you’re a contractor looking for pricing details or handling government construction projects.

This piece will show you everything about creating winning RFQs for your construction projects. We’ve packed it with practical examples and ready-to-use templates that cover simple steps and best practices to help you succeed.

Understanding RFQs in Construction

RFQs play a vital role in making project procurement smoother in the construction industry. Let’s look at what they mean and how they work in construction.

What does RFQs in construction mean?

The construction industry uses RFQ in at various project stages two different ways[1].

A Request for Qualifications is a formal document that project owners use to check contractors’ credentials before they submit complete proposals [2]. This screening tool helps them find contractors who have the right experience, capabilities, and financial stability for specific construction projects [1]. Contractors respond to this type of RFQ by submitting a Statement of Qualifications (SOQ) that shows they meet the project’s requirements [1].

RFQ also stands for Request for Quote. General contractors use this document during the change order process to figure out specific costs of needed changes [1]. You’ll see this version most often in change management software when owners need prices from general contractors or when GCs need prices from specialty contractors.

Both types of RFQs are the foundations of the procurement process. They help organizations find the right contractors based on their qualifications or get detailed pricing for specific construction work.

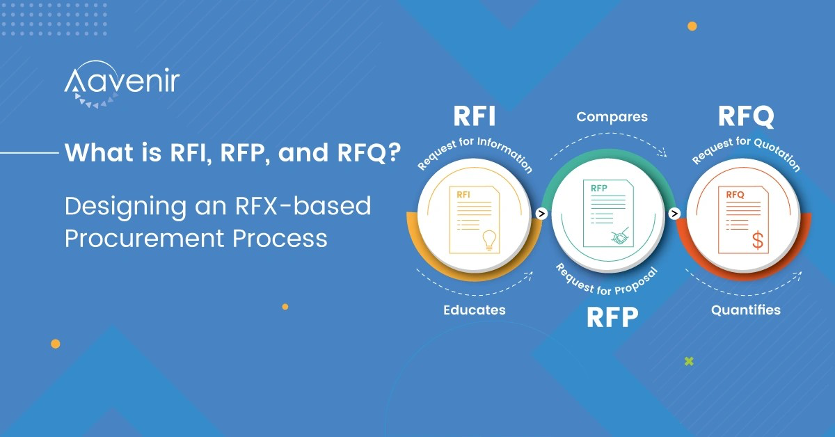

RFQ vs RFP vs RFI: Key differences : RFQs in Construction

Project managers need to know the difference between these three construction documents:

- RFQ (Request for Qualifications/Quote): Looks at contractor qualifications or specific pricing details. You use it when you know exactly what you need [3]. RFQs focus on costs and payment terms for well-defined requirements [4].

- RFP (Request for Proposal): Asks for complete proposals about methods and costs to build a specific project [1]. RFPs welcome new ideas and solutions. Vendors submit detailed information about their approach to the project [3].

- RFI (Request for Information): Helps clear up information about project details, including parts of documents like specifications, drawings, or agreements [1]. Teams use RFIs to gather general information during early project phases [4].

The biggest difference is their purpose. RFQs check qualifications or costs, RFPs look for detailed solutions, and RFIs gather general information [4].

When to use an RFQs in Construction

Request for Qualifications works best as step one in a two-stage procurement process [1]. Project owners first send out an RFQ to prequalify contractors, then send an RFP to the contractors who made the cut.

RFQs are perfect for these situations:

- You need to check potential suppliers’ qualifications and capabilities before moving to the next bidding stage [2]

- Public projects with a set budget and a guaranteed maximum price (GMP) contract might pick a contractor just based on their SOQ [1]

- High-volume/low-value items that need quicker completion than an RFP process [5]

- You know exactly what you need, how much you need, and the quality standards [6]

- Buying goods or standard items where price or delivery time matters most [6]

Public and private project owners often use RFQs to screen contractors before asking for proposals. This helps make sure that even the lowest bidder can handle the project properly [1].

Essential Components of a RFQs in Construction

Image Source: ProQsmart

A well-laid-out RFQ serves as the cornerstone of successful construction procurement. You’ll get more accurate quotes and smoother project execution when you include all the necessary components.

Project and contractor information – RFQs in Construction

The opening section of your construction RFQ should establish the key players and project details. Your company’s letterhead with contact information and simple project specifics like location and name should be front and center [4]. Government contracts need a complete along with a clear project number or identifier statement of the work[7].

On top of that, it should ask for specific contractor details such as:

- List of team members who will participate in the project

- Portfolio showing past experience with similar projects

- Safety information, including ratings and safety plans

- Financial information like cash flow statements or balance sheets

- Proof of bonding or insurance (bid bonds, performance bonds, general liability)

- References from relevant contacts (past project owners, architects, city officials) [8]

These details help you verify the credibility and capabilities of potential vendors right from the start.

Scope of work and technical requirements – RFQs in Construction

The is maybe the most critical part of an RFQ scope and requirements section[4]. You need to spell out exactly what needs to be delivered because unclear requirements create confusion and lead to inaccurate pricing [1]. RFQs in Construction

Your technical requirements should list:

- Detailed product or service descriptions with specific parameters

- Quantities needed for each item

- Technical specifications including materials, techniques, and required standards

- Preliminary drawings or schematics detailed enough for accurate quantity take-offs

- Site constraints and logistics information (access issues, environmental concerns)

- Project-specific safety protocols and compliance regulations [1][3]

So, providing detailed technical data helps vendors develop accurate construction budgets without guesswork.

Submission guidelines and deadlines

Clear submission instructions substantially increase your chances of getting complete, comparable bids [3]. This section should specify:

- Submission deadline date and time

- Method of submission (portal, email, etc.)

- Format requirements for the response

- Q&A protocols, including how to ask questions and question deadlines

- Pre-bid meeting schedules or site visit opportunities [1][7]

In fact, giving bidders enough time to process information is vital, especially for detailed bids. They need time to gather input from subcontractors and supplier partners [3]. The timeline for project execution should clearly show milestone dates for permit submission, predicted start date, and move-in deadlines [3].

Evaluation criteria and terms

The last key component brings transparency to bid evaluation and selection. This section should cover:

- Selection criteria (experience, cost, schedule, sustainability, etc.)

- Relative importance of each criterion (which factors carry more weight)

- Terms and conditions that will be part of the project contract

- Payment schedules and retainage percentage

- Procedures for handling scope disputes and change orders [1][3]

Creating a matrix to identify the project’s key criteria and sharing it with bidders helps them focus on what matters most to you [3]. Notwithstanding that, remember to include standard legal requirements like insurance specifications and performance guarantees to protect everyone throughout the project lifecycle [9]. RFQs in Construction.

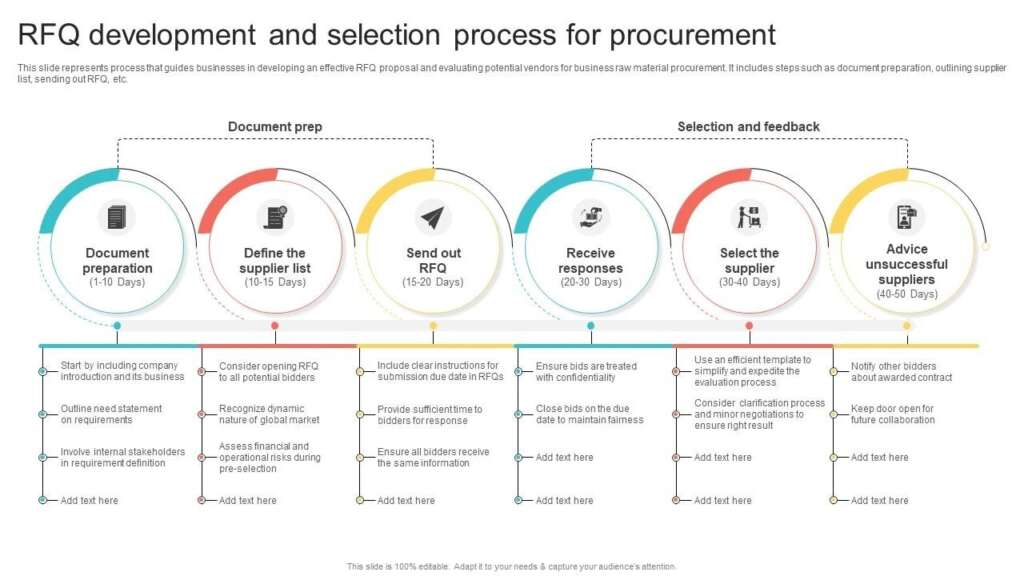

Step-by-Step Process to Create a Winning RFQ

Image Source: SlideTeam

Creating construction RFQs that work requires good planning and execution. Here’s a proven five-step approach that will help you create RFQs to attract the right vendors and make your projects successful.

1. Define your project needs clearly

You need to cooperate with managers and stakeholders to define your project’s purpose and scope. This preparation phase helps streamline the bidding process. Meet with department heads to get their input on requirements. You should establish clear specifications about:

- Project purpose and objectives

- Detailed scope of work

- Required quantities of materials or services

- Budget parameters to guide bidders

- Realistic timelines for project completion

After these meetings, pick a point person who will handle questions throughout the RFQ process. This creates a single source of information for potential bidders.RFQs in Construction

2. Choose the right vendors

After establishing project needs, research potential vendors well. The quickest ways include:

- Searching industry-specific directories and databases

- Getting recommendations from colleagues or other companies

- Using relationships with existing vendors

- Posting open bids when appropriate

You’ll need to decide between a large pool of vendors or a smaller, pre-vetted group. Pre-qualification helps ensure vendors have the right qualifications and experience for specialized construction projects.

3. Draft the RFQ document

Keep your vendors in mind as you create your RFQ document. Using a template saves time and ensures you include all information. Your document should spell out:

- Contact information for both buyer and vendor

- Submission requirements and deadline

- Detailed project scope and specifications

- List of products or services with quantities

- Selection criteria and evaluation method

- Terms and conditions

- Supporting documents like designs or schematics

The better you explain your business needs, the easier it becomes to pick the perfect vendor.

4. Distribute the RFQ to vendors

Send your finished RFQ and supporting documents to selected vendors. Make sure to include:

- Clear submission deadline

- Enough response time for thoughtful quotes

- Point of contact information for questions

- Method of submission (email, portal, etc.)

The tender phase requires equal treatment of all suppliers to maintain transparency and fairness. Give similar information to all vendors and keep any confidentiality requirements outlined in your RFQ.

5. Manage vendor questions and clarifications

Handling questions well leads to accurate bids. Set up a standardized clarification process by:

- Setting up a formal Q&A system

- Keeping records of all correspondence

- Sharing answers with all bidders for fairness

- Giving quick responses to prevent delays

- Posting clarifications in one central place

This approach gives consistent information to all plan holders and creates one reliable source of information. You’ll end up with more accurate quotes and fewer misunderstandings.RFQs in Construction

Examples and Templates to Guide You

Real-world examples and templates help you create RFQs for construction projects. The right formats and models will boost your procurement process.

Sample RFQ for construction materials

Construction material RFQs work best with a that lists building materials, equipment, and timelines table format[10]. A good construction materials RFQ needs:

- A letterhead with company contact information

- Project name and location identifiers

- A breakdown chart with columns for items needed, quantities, descriptions, and quote spaces [4]

To name just one example, a commercial complex construction project might list concrete quantities with specific units and clear pricing [11]. This layout helps vendors give accurate quotes because they know exactly what materials the project needs.

Template for electrical subcontractor RFQ

Electrical subcontractor RFQs need special design elements to price electrical materials, equipment, and labor [10]. A complete electrical RFQ template usually has:

- Customer-facing proposal with Good-Better-Best options

- Billing and payment information collection sheet

- Job costing breakdown for materials and labor [12]

Industry standards say electrical RFQs must show licensing requirements—most areas need contractors to have valid C-10 Contractor licenses[13]. These RFQs typically cover work related to electrical wiring, conduit, panels, telecommunications, security, lighting systems, and energy-efficient installations [13].

How to use a Bill of Quantities (BOQ)

BOQ plays a key role in the RFQ process, especially on bigger construction projects [2]. It gives a detailed list of materials and services needed for a project, including:

- Materials specifications with precise quantities

- Labor requirements with estimated hours

- Exact measurements for all components [2]

Architects or engineers create the BOQ through a takeoff process after they finish the project design [2]. Contractors price the BOQ and send it back to the owner who reviews and selects the contractor [2]. The BOQ becomes the schedule of values during the project, which makes progress calculations easy based on completed work [2].

This method makes comparing contractor proposals simple because each bidder quotes similar labor and materials [2].

Best Practices for Better Results

Your RFQ outcomes in construction projects can improve with proven best practices. These guidelines ensure accurate bids and help build stronger vendor relationships.RFQs in Construction

Be specific and avoid vague language

, bad bids, and expensive change orders later Generic RFQs lead to confusion[1]. Each request should include detailed scope specifications, preliminary drawings, site constraints, and required compliance regulations. This level of detail prevents misunderstandings and helps vendors provide accurate quotes.RFQs in Construction

Set realistic timelines

Construction timelines need careful planning. The process should to improve bid quality include buffer periods for vendor replies[14]. Vendors participate more when deadlines are realistic [14], and stakeholders stay accountable. Project milestone dates, permit submissions, and predicted start dates need precision [3].

Use a scoring system for evaluation

A clear evaluation criteria helps vendors understand how you’ll judge their proposals [15]. The RFQ should document weighted factors (e.g., cost 30%, technical approach 40%, experience 20%) [15]. This organized method makes evaluation objective and defensible.

Maintain transparency with vendors

An honest competitive bidding process needs transparency [16]. All participants deserve equal access to information and similar evaluation criteria [5]. Building trust with vendors requires immediate updates throughout the procurement process—from the original tender to evaluation [5]. Queries should go through a single point of contact to keep everything consistent [5].RFQs in Construction

Conclusion

RFQs play a vital role in today’s competitive construction world. This piece explores how RFQs work in two ways – as Requests for Qualifications to screen contractors and as Requests for Quotes during change orders. These documents help streamline procurement and save time while maintaining project quality.

Successful construction professionals know RFQs need careful attention to detail. Your documents should include complete project information, detailed scope requirements, clear submission guidelines, and transparent evaluation criteria. Inaccurate bids can get pricey and cause project delays and disputes.

The five-step process will help you get better RFQ results. Start by defining project needs through teamwork. Research and pick the right vendors before writing a detailed RFQ document. Once distributed, handle questions systematically to keep the bidding process fair and open.

Sample templates give you shortcuts to create effective RFQs. You’ll find formats for construction materials, electrical subcontracting, and Bills of Quantities that help standardize your approach. These tools ensure you don’t miss anything important.

Good practices determine how well your RFQ works. Clear details remove confusion. Realistic timelines attract quality bids. Well-laid-out scoring systems make evaluation easier, and openness builds trust with vendors. These elements are the foundations of successful project procurement.

Note that an RFQ is more than just paperwork – it sets expectations, builds relationships, and influences your project’s direction. Becoming skilled at this vital business document will give you an edge, whether you’re seeking new opportunities or looking for qualified partners. Put these strategies to work today and watch your construction procurement change from a challenge into an advantage. RFQs in Construction

Key Takeaways

Master these essential RFQs in construction strategies to streamline your construction procurement process and secure better project outcomes:

• Define scope precisely: Vague requirements lead to inaccurate bids and costly change orders – include detailed specifications, quantities, and technical requirements

• Use the two-step process: Start with Request for Qualifications to prescreen contractors, then follow with detailed pricing requests to qualified vendors only

• Structure evaluation transparently: Create weighted scoring systems (cost, experience, technical approach) and share criteria upfront to ensure fair, objective vendor selection

• Manage timelines strategically: Allow sufficient response time for quality bids while setting realistic project milestones and clear submission deadlines

• Maintain vendor relationships: Use single points of contact, answer questions promptly, and share clarifications equally to build trust and encourage participation

Effective RFQs serve as the foundation for successful construction projects, transforming procurement from a challenge into a strategic advantage that saves time, reduces costs, and ensures quality outcomes.

FAQs

Q1. What are the key components of an effective construction RFQ? An effective construction RFQ should include detailed project information, a clear scope of work, technical requirements, submission guidelines with deadlines, and transparent evaluation criteria. It’s crucial to be specific about materials, quantities, and project timelines to receive accurate bids.

Q2. How does an RFQ differ from an RFP in construction projects? An RFQ (Request for Quote) focuses on gathering specific pricing details or contractor qualifications, while an RFP (Request for Proposal) solicits comprehensive proposals about methods and costs to build a project. RFQs are more specific and typically used when you know exactly what you need, whereas RFPs are more open to ideas and solutions.

Q3. What strategies can improve the success of an RFQ in construction? To improve RFQ success, define project needs clearly, choose the right vendors, draft a comprehensive document, distribute it effectively, and manage vendor questions systematically. Using a scoring system for evaluation and maintaining transparency with vendors are also crucial best practices.

Q4. How should timelines be managed in the RFQ process? Set realistic timelines that allow sufficient time for vendors to prepare quality bids. Include buffer periods for vendor replies and be precise about milestone dates, permit submissions, and anticipated start dates. This approach increases vendor participation and maintains accountability among stakeholders.

Q5. What role does a Bill of Quantities (BOQ) play in the RFQ process? A Bill of Quantities (BOQ) is a detailed list of materials, labor, and services required for a project. It’s typically used in larger construction projects as part of the RFQ process. The BOQ allows for quick comparison between contractor proposals since every bidder quotes identical labor and materials, making the evaluation process more straightforward.RFQs in Construction

References

[1] – https://planyard.com/blog/mastering-the-rfq-process-in-construction

[2] – https://www.procore.com/library/bill-of-quantities-construction

[3] – https://www.mcdonaldyork.com/best-practices-for-producing-an-effective-rfq/

[4] – https://gobridgit.com/blog/construction-rfq-guide/

[5] – https://www.turnerandtownsend.com/insights/five-ways-to-achieve-transparency-in-your-procurement/

[6] – https://www.coupa.com/blog/rfi-rfq-rfpwhats-difference/

[7] – https://des.sc.gov/sites/des/files/Documents/BOW/SRF/RFQ_Guide.pdf

[8] – https://www.procore.com/library/what-is-an-rfq

[9] – https://www.astate.edu/a/procurement/vendor-information/files/rfq terms 2017.pdf

[12] – https://www.servicetitan.com/templates/electrician/bidding

[14] – https://proqsmart.com/blog/10-essential-elements-every-construction-rfq-should-include/

[16] –https://constructionclaims.com/Content_Free/91710part3.aspx